Vapor Corrosion Inhibitor Film

Control rust on metal products more safely and efficiently.

The vapor corrosion inhibitor (VCI) film is a highly safe and reliable product made by evenly incorporating a vapor corrosion inhibitor as its main ingredient into polyethylene resin. When metal products are wrapped in this film, the inhibitor gradually vaporizes or precipitates within the film, providing effective anti-corrosion protection.

Corspec’s VCI film is widely utilized across various industries, including automotive, machinery, and steel manufacturing. It offers durable, long-term protection against corrosion, ensuring the integrity of metal products over extended periods.

Features

- 1.

Offers immediate and long-lasting anti-corrosion effects.

- 2.

Film selection can be tailored to the contents and intended use.(Color customization is also possible.)

- 3.

Heat sealing can be performed easily.

- 4.

Transparent film allows for easy identification of contents, making storage more convenient.

- 5.

Combines anti-corrosion and packaging in a single process, improving workflow and reducing costs.

- 6.

Can be used with automatic packaging machines.

- 7.

Does not emit toxic gases during combustion and can be recycled like polyethylene.

Applications

- 1.Anti-corrosion for electronic circuit boards and precision machine parts.

- 2.Protection for automotive parts that use multiple types of metals.

- 3.Corrosion prevention for large machinery, metal components, and molds.

- 4.Anti-rust protection for steel materials.

- 5.Protection for machinery, equipment, and various components.

- 6.Temporary anti-corrosion during production line storage.

- 7.Protection for aircraft engine interiors and parts.

- 8.Anti-corrosion for export packaging.

Not limited to iron, Corspec's VCI film is effective for multi-metal protection, including various alloys. It provides efficient corrosion prevention for parts composed of multiple metals, such as those in automobiles and electronic components. Additionally, the film has no adverse effects on plastics, elastomers, or other non-metallic surfaces, nor does it interfere with optical functions.

Supply Forms

Product Types

| Category | Model | Applicable Metals |

|---|---|---|

| For Iron | CORSPEC-FM | Iron and cast steel |

| For Iron & Non-ferrous Metals | CORSPEC-CP | Copper and copper alloys, aluminum, silver products, etc. |

| For Iron & Non-ferrous Metals | CORSPEC-FNF | Iron and cast steel, copper and copper alloys, aluminum, etc. |

Custom orders are available for all categories: for iron, non-ferrous metals, and multi-metal. Film thicknesses range from 0.06 mm to 0.15 mm. Please specify the desired width and length.

We will confirm the producible sizes and contact you. The minimum production lot may vary depending on the thickness, width, and length, so please feel free to contact us for further details.

For large items (molds, machinery, etc.), instead of manufacturing large bags, it is recommended to purchase standard roll-wrapped products and wrap the target object with the film, which is a more cost-effective anti-corrosion method.

When inquiring, please provide the material of the object to be protected (iron, aluminum, copper, a combination of iron and copper, etc.), the intended use (for export, storage, transportation, etc.), and the desired anti-corrosion period.

Examples of Manufacturing Forms

Various forms are available, including flat bags, square-bottom bags, cut sheets, sheet rolls, and tube rolls. Color customization is also possible.

Cost Reduction Effects

By switching to Corspec's vapor corrosion inhibitor (VCI) film, preprocessing becomes unnecessary. Products can be shipped simply by wrapping them in film. The receiving side also saves time and effort as they can proceed directly to the next step without cleaning after unpacking. This reduces time, labor, and costs associated with preprocessing and cleaning.

【Current Workflow】

- Product manufacturing→

Anti-corrosion oil application

→ Packaging and shipping→ Receiving and unpacking→Cleaning

→ Product usage

【With Corspec VCI Film】

- Product manufacturing→ Packaging and shipping→ Receiving and unpacking→ Product usage

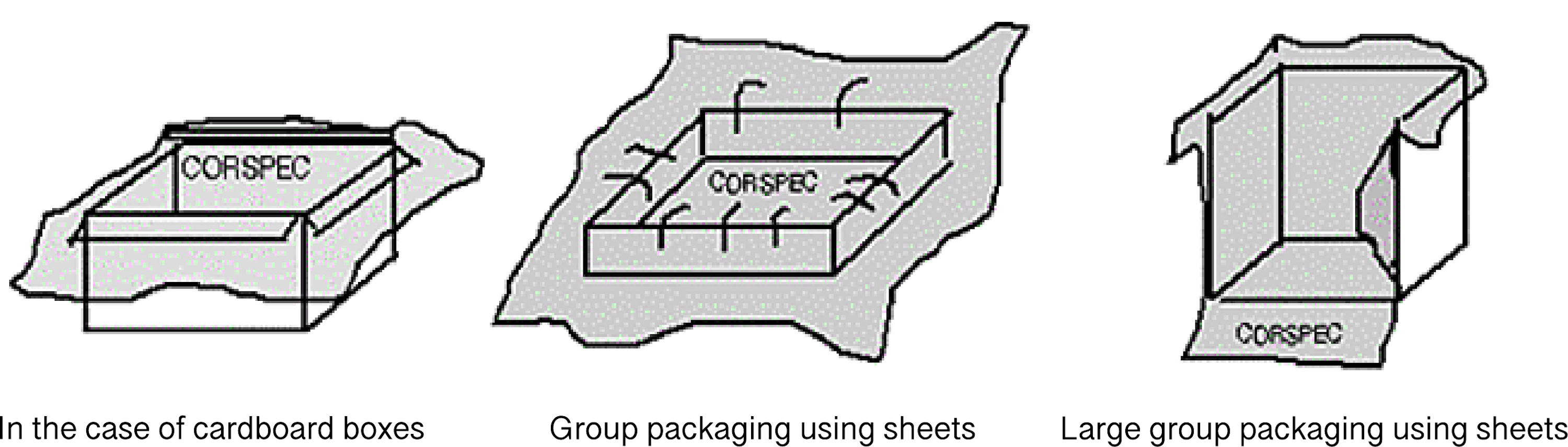

Packaging Examples & Storage Methods

① Individual Packaging

- Manual: Heat sealing or vacuum sealing for airtight packaging.

- Semi-automatic: Airtight semi-automatic packaging using endless sealers or L-type sealers.

- Automatic: Horizontal pillow packaging machines or vertical pillow packaging machines.

- Large-scale: Overlapping, hand sealers, or tape bonding methods.

② Bulk Packaging

Storage Methods

- Vapor corrosion inhibitors (VCI) decrease over time due to evaporation.

- Avoid long-term storage in high-temperature and high-humidity environments, as evaporation loss depends heavily on vapor pressure, temperature, and humidity.

- Store in a dry, cool, and dark place away from direct sunlight, similar to general chemical storage methods.

- In normal work areas, a few days of exposure does not cause significant issues, but it is recommended to open the packaging right before use. Seal any remaining quantity tightly to store.

※ The effectiveness of vapor corrosion inhibitors is greatly affected by sealed conditions. To prevent the gas from dispersing into the air, it is essential to use the product in a tightly sealed environment.

Battery

Battery